Discover the Benefits of an AI Bottle Filling Complete Setup with Robotsmarketplace1

If you’ve been searching for a high-tech and efficient solution to elevate your water bottling production, look no further. Welcome to the world of the AI Bottle Filling Complete setup. Employing artificial intelligence in manufacturing processes is no longer a thing of the future. It’s here, and it’s revolutionizing the way bottling factories operate. Specifically, our AI Bottle Filling Complete setup offers an unrivaled automatic water production line that is designed not only to quicken bottling procedures but also to guarantee accuracy, hygiene, and optimal use of resources.

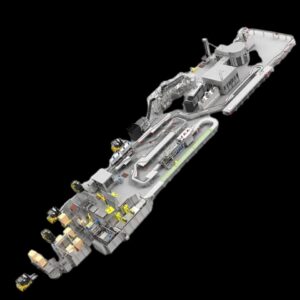

The AI Bottle Filling Complete setup is composed of several advanced machines, each with its distinct role to play in the complete process of bottled water production. We offer the following:

- Bottle blow molding machine: This machine takes care of forming plastic bottles according to size and design specifications. The process encompasses the heating and inflation of preforms into the shape of the bottle. By leveraging AI, the machine can deliver precisely shaped bottles without any errors.

- Air conveyor: Post the molding of the bottles, the air conveyor serves the task of transporting these bottles to the filling machine. This task, though seeming simple, is actually carefully planned and executed to ensure minimal damage and maximal efficiency.

- 3 in 1 filling machine, or Combiblock machine: This novel machine undertakes three significant tasks – rinsing, filling, and capping, rolled into one sleek unit. Its performance is meticulously controlled by AI to ensure clean bottles, accurate filling, and precise capping.

- Bottle conveyor and light checking: Post filling and capping, the bottle conveyor ensures efficient and secured bottle transfer while the light checking method ensures the integrity of the filling process. Any errors or inconsistencies are detected by AI and are immediately corrected.

- Bottle dryer and date coding machine: The final stages include drying the bottles after labeling and coding each bottle with the date, batch number, and other relevant details. By using AI, the coding is neatly performed without any overlapping’s or misreads.

The AI Bottle Filling Complete setup is a perfect combination of technology and precision, designed to take your water bottling business to new heights. Invest in the future today, and witness the remarkable difference.

Acquiring an AI Bottle Filling Complete setup would be a game-changer for any water bottle production enterprise. This machine line combines automation and artificial intelligence, designed to yield high productivity, efficiency, and impeccable consistency. Let’s delve into the fascinating elements of our automated water bottle production line.

Key Components of the AI Bottle Filling Complete Setup

The high-speed, error-free operation of the AI Bottle Filling Complete setup is as a result of the following components working in harmony:

- Bottle blow molding machine: This is the first piece of the puzzle, a mechanism designed to shape your bottles into the desired form accurately and swiftly.

- Air conveyor, 3 in 1 filling machine (or Combiblock machine): With this, your bottles are transported efficiently to the filling stage where the 3 in 1 machine fills up your bottles precisely, under strict quality control.

- Bottle conveyor and light checking: After filling, every bottle takes a ride on the conveyor system toward the light checking station. This process involves the use of a light checker to ensure that all filled bottles meet the quality standards.

- Bottle dryer and date coding machine: The drying stage comes next, where high-speed blowers effectively dry the bottles. Immediately after drying, the date coding machine inscribes the production date and other necessary information on the bottles.

From the molding to the coding, the AI Bottle Filling Complete setup ensures that every step of your water bottle production process is automated and perfected, saving time and improving productivity.

Why Choose The AI Bottle Filling Complete Setup?

Choosing the AI Bottle Filling Complete setup isn’t just about embracing innovation; it’s about securing a future-proof investment for your water bottling business. Its automation inherently results in faster production times and nearly eliminates the possibility of human error. The artificial intelligence aspect ensures that the setup operates smoothly while delivering the highest standard of precision in every task it performs. Additionally, our AI Bottle Filling Complete setup is eco-friendly, minimizing waste and promoting a sustainable environment.

Before we delve deeper into the AI Bottle Filling Complete setup, let’s understand its component parts. This enlightening overview provides you with a clear and precise picture of how this state-of-the-art product works and integrates seamlessly into your production line.

Components of the Automatic Bottle Water Production Line:

- Bottle blow molding machine

- Air conveyor and 3 in 1 filling machine (or Combi-block machine)

- Bottle conveyor and light checking

- Bottle dryer, date coding machine, and more

Now that we understand the components of the AI Bottle Filling Complete setup, let’s look at how they work together to form a seamless, effective production line, ensuring a quicker ROI and enhanced efficiency in your bottling business.

Note: The AI Bottle Filling Complete setup is designed to be environmentally friendly, minimizing waste and promoting a sustainable environment. Your business isn’t just improving its bottom line, but also helping to create a sustainable planet.

How the AI Bottle Filling Complete setup Works

First, the bottle blow molding machine shapes the preform into the desired bottle shape. The machine has been fine-tuned to work with precision, ensuring error-free and consistent results.

Changeover to the air conveyor, which swiftly and carefully transports the newly molded bottles to the 3 in 1 filling machine. This part of the AI Bottle Filling Complete setup is intelligently programmed to prevent any damage or contamination to the bottles during transit.

Next, the actual filling of the water takes place in the 3 in 1 filling machine. This component of the setup is where the AI really shines, as it monitors every fill to ensure the correct volume of water is dispensed into every bottle, every time.

Then, the bottle conveyor moves the filled bottles to the light-checking area. If a bottle is mistakenly filled or there is any other type of error, our smart AI will detect it and promptly remove the defective bottle from the production line.

Lastly, a date coding machine stamps the production date and other pertinent information onto the bottle. All the while, a bottle dryer ensures that each bottle is completely dry before the final packaging.

With intelligent systems at its core, the AI Bottle Filling Complete setup is your business’ answer to a high-productivity, error-free, and sustainable future.

The Importance of AI Bottle Filling Complete setup

If you’re in the beverage industry, you’re probably aware of the tediousness and precision that bottle filling requires. But, did you know that there’s an efficient and flawless solution to this? Let us introduce to you the AI Bottle Filling Complete setup. It’s a game changer, revolutionizing the bottling industry with increased speed, efficiency and accuracy.

Understanding the AI Bottle Filling Complete Setup

AI in this context refers to ‘Automatic Intelligence’. The AI Bottle Filling Complete Setup is a comprehensive, automated solution for bottle filling. It consists of state-of-the-art machinery and sophisticated technology that work seamlessly together to provide optimal efficiency and productivity in bottle filling processes. What’s more exciting is that you’re not just getting a mere bottle filling machine. This setup includes:

- Bottle blow molding machine

- Air conveyor, 3 in 1 filling machine, or combiblock machine

- Bottle conveyor and light checking

- Bottle dryer and date coding machine

Note: This is a compact, fully integrated system that has been meticulously designed for high-speed production with unmatched accuracy.

With this setup, you’re not just buying a product, you’re investing in a solution that streamlines and elevates your entire production line.

What Makes the AI Bottle Filling Complete Setup Stand Out?

One word – automation. The AI Bottle Filling Complete setup leverages the best of automation and cutting-edge technology. With very little human intervention needed, your filling process becomes smoother, faster, and more reliable. The lower risk of manual errors means your consistency, accuracy, and quality are maintained at their peak at all times.

Buy AI Bottle Filling Complete setup from robotsmarketplace1.com

Imagine a world where bottling and packaging of beverages are completely automated, efficient, and devoid of human errors. That idea is no longer a fragment of imagination but a reality with the introduction of the AI Bottle Filling Complete setup. This automated system incorporates the most advanced artificial intelligence technology to revolutionize the bottle filling process in industries. But what exactly is this remarkable machine composed of and how does it work? Let’s find out.

Key Components of the AI Bottle Filling Complete Setup

Every AI Bottle Filling Complete setup consists of several key components, each designed to perform a specialized function to ensure a seamless, efficient production. These components include:

- A bottle blow molding machine to create the shape of the bottles

- An air conveyor to move the empty bottles to the filling machine

- A 3 in 1 filling machine, or combiblock machine, for synchronization of filling, capping, and sealing

- A bottle conveyor and light checking system for quality control

- A bottle dryer and a date coding machine for final touches before packaging

Together, these components work symbiotically to optimize the bottle filling process, cutting down production time and reducing manual labor.

Why Choose The AI Bottle Filling Complete Setup?

Choosing the AI Bottle Filling Complete Setup means you’re investing in efficiency, precision, and the future of the bottling industry.

The AI Bottle Filling Complete setup is not your regular bottle filling station. It utilizes AI technology to increase efficiency, reduce errors, and streamline operations. Whether you’re in the beverage, pharmaceutical, or any other industry that requires bottle packaging, this setup can be easily integrated into your production line. With its futuristic technology, it assures optimal operations, a decrease in production costs, and an increase in output quality.

Exploring the Components of an Automatic AI Bottle Filling Complete Setup

The world of technology has seen many advancements over the years and one such innovation is the Automatic AI Bottle Filling Complete Setup. This is an intelligent, automated system designed to streamline the process of filling bottles in a fast and efficient manner.

Designed with precision and careful engineering, the Automatic AI Bottle Filling Complete Setup ensures a seamless flow of operations, all the while reducing manual labor and improving the overall efficiency and production. This setup combines multiple components which include:

- Bottle blow molding machine

- Air conveyor

- 3-in-1 filling machine

- Light checking and bottle conveyor

- Bottle dryer and date coding machine

Together, these individual components form an interconnected system that ensures the swift, seamless, and error-free operation of filling bottles. This setup combines the power of artificial intelligence with advanced robotics, paving the way for industrial automation.

Importance of the Automatic AI Bottle Filling Setup

The Automatic AI Bottle Filling Complete Setup is transforming the dynamics of the production world. It efficiently speeds up the traditional bottleneck process of bottle filling, reducing the time and resources required for the task, making it increasingly budget-friendly and economically sustainable. This is a giant leap for businesses aiming to move towards complete automation, reducing the need for human involvement, and hence, minimizing errors.

“Automation in the production industry, especially in bottle filling processes, is a game-changer. The ‘Automatic AI Bottle Filling Complete Setup’ is an exemplary blend of advanced AI and automation techniques, offering incredible speed, precision, and efficiency.”

| Components | Roles |

|---|---|

| Bottle blow molding machine | Produces bottles to be filled |

| Air conveyor | Transports the bottles to the filling machine |

| 3-in-1 filling machine | Fills the bottles accurately in a high-speed manner |

| Light checking and bottle conveyor | Checks the quality and transports filled bottles for further processing |

| Bottle dryer and date coding machine | Dries the bottles and adds the date codes respectively |

Therefore, the Automatic AI Bottle Filling Complete Setup is an incredible way to revolutionize your production line, save on costs, and increase output through advanced automation. It’s time to take advantage of this technological advancement and boost your production efficiency.

Bottle Blow Molding Machine: Revolutionizing Bottle Production

As technology advances, so does efficiency in production. The AI Bottle Filling Complete setup is reshaping how bottling companies operate, with the bottle blow molding machine at the forefront of this revolution. This ingenious system produces high-quality bottles quickly, drastically minimizing the production costs and time.

What is a Bottle Blow Molding Machine?

A bottle blow molding machine is a device used to produce high volume bottles using the blow molding process. During this process, a heated plastic tube, called a preform, is inflated into a mold to take its shape. Blow molding produces one-piece, seamless bottles efficiently and cost-effectively with minimal waste, making it a critical component of the AI Bottle Filling Complete setup.

Benefits of using a Bottle Blow Molding Machine in the AI Bottle Filling Complete setup

- Efficiency: The machine can produce an astonishing number of bottles in record time, drastically optimizing production levels.

- Quality: Blown bottles are uniform and free from imperfections thanks to the mold shaping process, increasing the overall quality of the finished product.

- Economy: The blow molding process reduces waste materials, thereby saving costs on raw materials and promoting eco-friendly practices.

- Customization: Different molds can be used for a variety of bottle shapes and sizes, providing options and flexibility in product design.

Bottle Blow Molding Machine functionalities in the AI Bottle Filling Complete setup

The bottle blow molding machine plays a pivotal role in the AI Bottle Filling Complete setup. Once it creates the bottles, they are transferred to the air conveyor. The bottles are then transported to the 3 in 1 filling machine, also known as a Combiblock machine, where they’re filled with the desired product.

Upon being filled, the bottles are moved along the conveyor, undergoing light-checking to certify their quality, followed by a trip through the bottle dryer. The last step of the AI Bottle Filling Complete setup process includes a date-coding machine, which ensures traceability of each product, providing crucial information such as production date and batch number before the bottles leave the production line.

Award-winning products deserve top-of-the-line production methods. Investing in an AI Bottle Filling Complete setup, powered by a bottle blow molding machine, could very well put your brand on the path to industry leadership.

3 in 1 Filling Machine (or Combiblock Machine): Streamlining the Filling Process

In our relentless pursuit of innovation, we proudly present the heart of our setup, the automatic AI bottle filling complete setup – a 3 in 1 filling machine, also known as a Combiblock machine.

The 3 in 1 filling machine is a crucial component when it comes to streamlining the process of bottle filling. This versatile piece of technology combines the tasks of bottle rinsing, filling and capping into one wholesome operation, significantly cutting down on production time and increasing overall efficiency.

This 3-in-1 system truly embodies the essence of the automatic AI bottle filling complete setup, by seamlessly integrating multiple operations and leveraging AI technology to ensure accuracy and consistency of each production cycle.

Key Features of the Combiblock Machine Following are the standout features that the 3-in-1 machine or Combiblock brings in our automatic AI bottle filling complete setup:

- Compact Design: Its architectural design optimizes the use of floor space. Furthermore, it’s easy-to-maintain structure facilitates smooth workflow.

- Efficiency: By combining the processes of rinsing, filling and capping, the Combiblock machine drastically reduces bottlenecks and streamlines production.

- Automation: The machine is equipped with an advanced AI that autonomously manages the production process, reducing the need for human intervention.

- Flexibility: With its ability to work with a range of bottle sizes and types, the machine offers flexibility like no other.

Table showing with some technical details of the Combiblock Machine in Automatic AI Bottle Filling Complete Setup

| Feature | Description |

|---|---|

| Operational mode | Automatic |

| Loading capacity | Up to several thousand bottles per hour depending on bottle size |

| Power requirement | 220V/380V |

| Weight | Approximately 3500 kg |

To conclude, the 3-in-1 Combiblock machine forms the backbone of our auto AI bottle filling complete setup. It encapsulates our vision to transform the way industries handle their bottling requirements, with better efficiency, accuracy and hustle-free operation.

FAQ’s

If you’re considering adding an AI Bottle Filling Complete setup to your production line, you may have a few questions. Below are some of the most frequently asked questions about our automatic AI bottle filling setup:

Q1. What actually is an AI Bottle Filling Complete Setup?

A: An AI Bottle Filling Complete Setup is a technologically advanced line dedicated to automating the process of bottling. It incorporates systems like the bottle blow molding machine, the 3 in 1 filling machine or a combiblock, air and bottle conveyors, light checking, bottle drying, date coding machines and more. It’s powered by artificial intelligence for more efficient operations.

Q2. What is the key advantage of using the AI Bottle Filling Complete Setup?

A: The primary advantage of using the AI Bottle Filling Complete setup is its automation capabilities and precision which eliminates errors, saves time, boosts efficiency and ultimately optimizes production processes.

Q3. Can I customize the AI Bottle Filling Complete Setup as per my needs?

A: Yes! The AI Bottle Filling Complete setup offers extensive customization. This allows you to integrate the setup perfectly with your existing operations and meet your specific production needs.

Q4. How does the Bottle Blow Molding Machine function in the AI Bottle Filling Complete setup?

A: The Bottle Blow Molding Machine plays a crucial role in the automatic AI bottle filling complete setup. It is responsible for creating the bottles that are then filled, capped, labeled and packaged by the other machines in the setup. It ensures uniformity in bottle quality and size.

Q5. What is the role of the Combiblock Machine in an AI Bottle Filling Complete setup?

A: The Combiblock machine is a core component of the AI Bottle Filling Complete setup. It serves multiple functions; each part designed to first clean, then fill and finally cap the bottles, offering a comprehensive solution for your bottling needs. Its sophisticated mechanisms are all engineered to work quickly and efficiently for faster production speeds.

Q6. Do you offer customer support for the AI Bottle Filling Complete Setup for troubleshooting and maintenance?

A: Of course! We value our customers and their satisfaction is our top priority. We offer a full range of customer support services including troubleshooting, maintenance, technical support and much more. Rest assured, when you buy the AI Bottle Filling Complete setup from us, you will receive the utmost support.

Conclusion

In conclusion, the AI Bottle Filling Complete Setup offers a revolutionary solution for automating your bottle production line. Its complete suite of components, including the bottle blow molding machine to the Combi-block machine, streamlines the production right from the creation of bottles to their filling and final checks.

This setup not only improves efficiency but also maintains a high degree of accuracy and consistency, key metrics for any successful production line.

The appealing features of the AI Bottle Filling Complete Setup makes it an impressive choice for businesses looking to upgrade their production lines. Whether you manage a small-scale unit or a large manufacturing plant, this versatile setup can cater to your needs and scale with your operation.

Furthermore, backed by AI, the setup is equipped to learn and improve over time, thus future-proofing your investment. Remember, quality and reliability are cornerstone values we uphold at our website, so you can always expect the best from our AI Bottle Filling Complete Setup.

So why wait? Head over to robotsmarketplace1.com to purchase your AI Bottle Filling Complete setup and start reaping the benefits today!

AI Bottle Filling Complete setup

buy the Automatic Drinking Bottle Water Filling unit, Bottling Packing Machine or cold drink bottle Production unit. AI Bottle Filling Complete setup

Product SKU: AIBFCS1

Product Brand: AI Bottle Filling Complete setup

Product Currency: USD

Product Price: 105000

Price Valid Until: 2023-12-31

Product In-Stock: InStock

5

Reviews

There are no reviews yet.